The types of projects that we undertake at Makersmith are so varied that each one brings it’s own unique challenges; no routine work for us! As a result we have to make sure that we learn as much as possible from each project and embed whatever we have learnt into the next.

An important part of this is time recording; it’s really easy to significantly underestimate the time taken to carry out a design or manufacturing task as we naturally tend to be optimistic when we envision a process. If, having carried out the task, we know exactly how long it took, then we are in a much better position to not only plan the next project timescale more accurately but to give our clients the most effective quotations for work.

Our Unconventional Guide is based on one day’s time logging for a project for one of our design team:

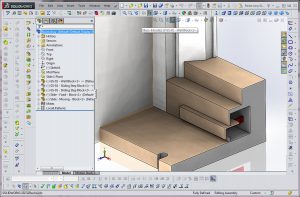

7:45am Arrive at work, coffee, review schedule for the day. Update project planner to record completed work. Check emails, check client emails into CRM system. Fire up SolidWorks ready to review project CAD model

8:22am Take call from client with detail query as they are on the way to work. Reassure them that we have resolved the query and will confirm with them by email before the end of the day. Log the call in the CRM system

8:27am First task this morning: resolve the design of connections between steelwork and timber components, build detail in to the outline concept model until it is completely resolved. Compare the solution with the the requirements of the detailed Project Specification –it’s in line with that. Review the detail to make sure there are no untested assumptions. Double check the availability of special fixings – they are normally a stock item. Record this and the full specification in the project Bill of Materials.

10:35am Really stop for coffee…

10:35am Really stop for coffee…

10:46am Prepare for client meeting at 1pm for new project. It’s great to have such an amazing meeting venue – the Old Kitchen at the Abbey – enough to excite any prospective client; make sure the room booking is confirmed…

Set up paperwork, initial documents and detailed specification questionnaire to run through with client. Make sure the computer Works!

11:33am Review key issues for new project and carry out research into alternative materials and suppliers.

12:07pm Lunch – a short walk in the woods and back for…

12:48pm To the Old Kitchen to check the setup.

1:15pm  Meet clients with colleagues. Chair meeting and lead through client requirements, detail specification issues, identify areas where we need more client information and where more research is needed. Conclude with summary of our respective actions and timescales to complete. All done.

Meet clients with colleagues. Chair meeting and lead through client requirements, detail specification issues, identify areas where we need more client information and where more research is needed. Conclude with summary of our respective actions and timescales to complete. All done.

14:30pm Return to office and complete meeting notes for project file/audit trail and summarise on CRM system.

15:07pm Check in the workshop to see progress of another project and evaluate stiffness of the structure – having done the design originally it’s good to see it in the flesh and to feel that it is just as designed.

15:22pm Back to detail project work. This time taking detail computer data out from SolidWorks for use in manufacturing systems to create laser cut steel profiles. Also take timberwork profile data for production.

16:02pm Use CNC tooling program to check the correct machining sequence for the timber. Revise the design slightly in SolidWorks to optimise machining time and re-check the CNC programme. All fine.

17:16pm Review emails that have arrived during the day and allocate responses to future time slots. Reply as necessary.

17:46pm Shut down the computer to go home. Leave through the workshop where the CNC machines are still running. Out into the evening air with the hazy view across to the hills and stumble over a flock of Quail that seem to be wandering around the car park and perching on the cars…

Another day at Makersmith…

Working within a defined framework means that designers have more freedom to focus on being creative without having to think too much about the overall process and whether they are on the right track. It’s a bit like going out for a walk and going from waymarker to waymarker. You can explore and admire the view but when you get to the next signpost you know you are on the right route to reach the end.

Working within a defined framework means that designers have more freedom to focus on being creative without having to think too much about the overall process and whether they are on the right track. It’s a bit like going out for a walk and going from waymarker to waymarker. You can explore and admire the view but when you get to the next signpost you know you are on the right route to reach the end.