Pulsar Instruments Plc, founded nearly 50 years ago, is an established and well-respected manufacturer of noise measurement instruments. The devices are used exclusively by health and safety professionals to monitor industrial noise levels and to ensure that they remain legal.

Makersmith were asked to manufacture structural framing to support Pulsar’s innovative SafeEar Max signs which can be wall or pole mounted in factories or worksites.

The front panel can be changed to provide hearing protection warnings or simply messages to encourage people to reduce noise.

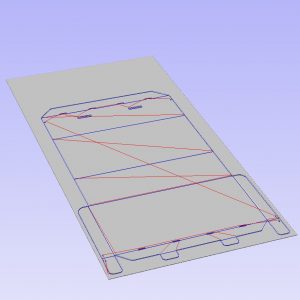

We manufactured and assembled the frames from CNC cut plywood sections so that they would be both cost-effective and stable.

Using plywood in this way allowed us to make the frame elements self-aligning so improving accuracy and simplifying assembly.

The client was really pleased and gave us the following feedback:

“Thanks for the wooden frames, they’ve been a great success for this project, providing suitable stiffness for the environments they’ll be used in plus the flexibility for the customer to mount them in various locations.”

It pay to think “outside the box” for structural products; see what we can do then talk to us and we can help with solutions in timber, steel and a wide range of other materials.

It’s been great to work with Pulsar Instruments who have a strong presence in the UK and sell products to over 40 countries around the world via an extensive distribution network. All Pulsar Instruments’ products are manufactured in the UK and are above all affordable, robust, easy to use, yet accurate.

You can find out more about Pulsar at www.pulsarinstruments.com or you can email the team at sales@pulsarinstruments.com or ring 01723 518011…