SPECIALIST MAKER

Do you have the flexibility, practicality and ability to make (almost) anything? That’s what we’re looking for…

Overview

Davies and Begbie are building a great creative team to deliver design and manufacturing services through our “Makersmith” brand and our own products through the “Two Green Leaves” brand.

We are small but have great visions that inspire us and want you to be inspired and share those visions too:

Our vision for Makersmith is:

“To be the UK’s most satisfying company; to be a place for businesses to come to create whatever they can’t buy off the shelf.”

And our vision for Two Green Leaves is:

“To enable people to create and enjoy their own sustainable environment”

We are driven by creativity, practicality and an enthusiasm for great design and our focus is on developing a profitable, inspiring and enjoyable business.

The role

As a Specialist Maker you will need to be really flexible. We are a small business but your role is crucial as you help make product and contribute to the product development process.

We want people who can take boring repetitive production work and think of ways of making it interesting and more efficient. We need people who can take a design for something they have never made before and make an excellent finished product. Above all we need people who are interested in what we do and are committed to excellence.

Responsibilities

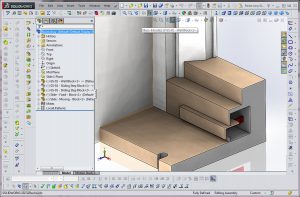

- Manufacture one-off and batch quantities of product in a range of materials including metals, timber, plastics and glass using a range of tools and equipment including manual hand tools, portable and bench mounted power tools and CNC equipment.

- Work on client sites when necessary to carry out surveys and to install product.

- Source and purchase materials and equipment to set budget & timescale

- Maintain production equipment and buildings.

- Set up and comply with Health and Safety systems and procedures

Requirements

Who you are is as important as what you can do; as a minimum we are looking for someone with these essential Hard Skills:

- Minimum of 12 months experience in a hands-on manufacturing environment

- Ability to read engineering and construction drawings

- A minimum of a current car driving licence with no endorsements.

- Able to use Microsoft Office products: Excel, Word, Outlook (Email) & PowerPoint

- Able to use the internet.

- Clear written communication with correct grammar & spelling. Ability to structure technical reports clearly and logically.

These desirable hard skills:

- Experience of 3D printing

- Metal fabrication experience

- Experience of model making

- Product painting and finishing

And these essential Soft Skills:

- Creative thinker – constantly seeking to improve and add value to specific products, processes and to the business as a whole.

- Able to engage confidently in internal team meetings and activities with clear and persuasive written and verbal communications.

- Able to engage with clients and suppliers through effective listening and good verbal and interpersonal skills.

- Demonstrable positive engagement and contribution to product manufacturing and business development in previous job roles.

- Attention to detail: able to efficiently deliver high quality products.

- Awareness of the important relationship between manufacturing time, quality and cost demonstrable through previous manufacturing experience.

- Capable of approaching tasks with a questioning attitude, making no assumptions about task requirements and available information.

- Adaptable and willing to carry out a wide range of tasks in a flexible job role that is responsive to client and market needs.

- A personal interest in making and great design.

Location

We have a great rural location in Wykeham, near Scarborough, North Yorkshire on the edge of the North Yorkshire Moors National Park and 6 miles from the sea – surfing, mountain biking and 1500km2 of National Park on your doorstep…

Hours and Benefits

We are open to the following employment options depending on experience and personal preference:

- Part time employment for 2 days per week at 7.5 hours per day

- Part time employment for 3 days per week at 7.5 hours per day

- Full time employment for 5 days per week at 7.5 hours per day

For all options we are offering a monthly salary based on an hourly rate of £9.30/hr to £12.80/hr depending on experience.

Potential for personal and career development in a small but expanding company where you can be really involved.

Recruitment Process

Please call this number: 01723 336151

And leave a voicemail in response to the message you hear.

If we would like to hear from you further, we’ll call you and ask for you to send us your CV

If we want to meet you, we will arrange for an initial interview where you will also be asked to carry out a DISC behavioural profile assessment.

Finally, we will interview a short list of candidates, check your references and make an appointment.

In your dreams… . Ideas do come from dreams, perhaps one of the most fundamental was Niels Bohr when he was inspired to describe the structure of the atom by a dream. You may dream of products, structures, shapes, landscapes, machines…

In your dreams… . Ideas do come from dreams, perhaps one of the most fundamental was Niels Bohr when he was inspired to describe the structure of the atom by a dream. You may dream of products, structures, shapes, landscapes, machines… Competition: “I want one like that” or “ I don’t want one like that” are both powerful drivers for creators of things

Competition: “I want one like that” or “ I don’t want one like that” are both powerful drivers for creators of things

10:35am

10:35am

Distributed Manufacturing

Distributed Manufacturing

Working within a defined framework means that designers have more freedom to focus on being creative without having to think too much about the overall process and whether they are on the right track. It’s a bit like going out for a walk and going from waymarker to waymarker. You can explore and admire the view but when you get to the next signpost you know you are on the right route to reach the end.

Working within a defined framework means that designers have more freedom to focus on being creative without having to think too much about the overall process and whether they are on the right track. It’s a bit like going out for a walk and going from waymarker to waymarker. You can explore and admire the view but when you get to the next signpost you know you are on the right route to reach the end.